Contents

- Current technology of salt transshipment

- Problem points of transshipment

- Weak links in transshipment technology

- Solutions for optimizing salt handling

- Conclusions

Current technology of salt transshipment

The current transshipment of bulk salt in Egypt is not much different from the transshipment of any other bulk cargo. High-sided tractor-trailers bring salt to the port to accumulate the ship’s cargo. The cargo is stored in covered warehouses at the port. After the vessel arrives, the salt is delivered on board or under the ship using a conveyor system or in conventional dump trucks. Shipboard cranes, rarely port cranes with grabs, transfer the cargo from the berth to the vessel’s holds. Vessel loading rates are about 7,000-10,000 tons per day.

Problem points of transshipment

This technology uses not only dump trucks, but also heavy-duty trailers to transport salt to the port’s warehouses. Storage requires large covered warehouses. From the port’s front warehouses, salt is transported by dump trucks to the ship’s side and poured out again on the berth under the ship’s crane grab. Here we observe at least two transshipment operations within the port’s technological process.

Weak links in transshipment technology

The use of specialized vehicles is always more expensive than universal vehicles. In the case of salt transshipment, at least two types of specialized vehicles are used.

Unloading salt first into a covered warehouse and then onto a berth leads to increased transshipment losses. In addition, there is a possibility of product contamination and fractional destruction. Working with such an aggressive cargo as salt leads to rapid depreciation of expensive fixed assets of enterprises.

At a rate of 7,000-10,000 tons per day, it takes 4 to 6 days to load a 35,000-50,000-ton vessel. This is not fast enough. The spot daily freight rate for this type of vessel varies from $13,000 to $15,000 per day at different times. Using the ship’s own cranes to load cargo increases the total amount of the freight.

Solutions for optimizing salt handling

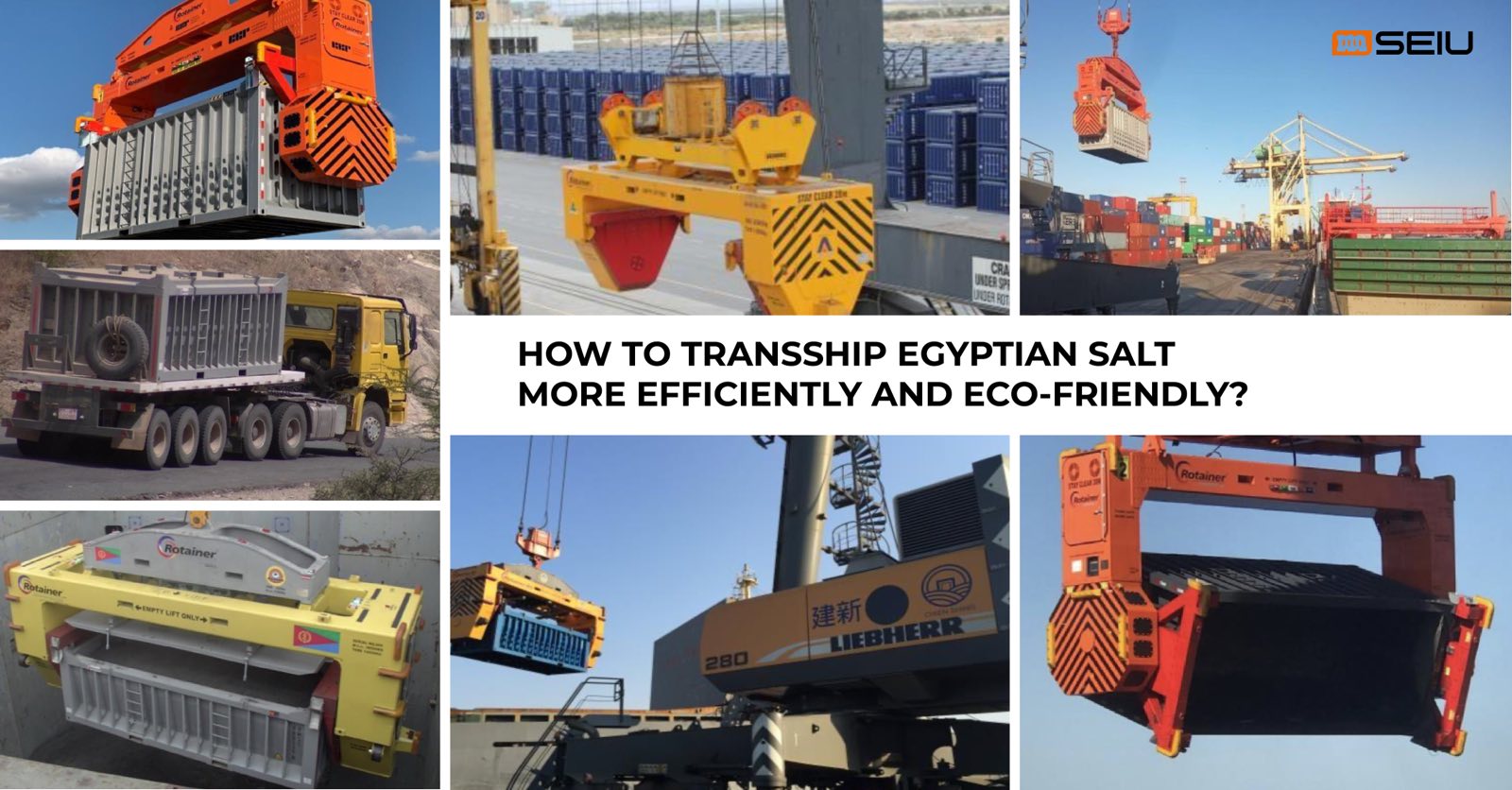

And now let’s imagine what would happen if universal, automobile container ships with 20-foot containers. They would replace the flatbed trucks and dump trucks in use. Obviously, fewer of them would be needed. Because the same container ships would work both at the factory-port warehouse and at the port warehouse-shipboard.

What if the cargo was stored in containers rather than in covered, floor warehouses at the port? Storing salt in closed containers in open areas of the port will be much cheaper and will not require large areas. Such storage will help avoid cargo losses during intermediate transshipment at the port’s covered warehouse and near the ship’s side.

Shore and container cranes can make up to 35 cycles per hour. And some champion operators even up to 50 cycles per hour. When loading 30 tons of salt in a 20-foot container , and using only one Rotainer, the vessel’s loading rates can reach 24,000 tons per day. Vessel type: Handysize, Handymax or Panamax will be loaded in 1.5 – 2 days without using their own cranes.

Conclusion

Containerized transshipment of bulk salt through a universal, containerized terminal will be much more efficient, environmentally friendly and cheaper than transshipment through a specialized terminal. Such transshipment will require fewer universal trucks. There will be no need to use the port’s covered warehouses. And the savings on vessel freight alone can amount to $40,000 to $48,000 per shipment.

Author: Mykola Soloviov

You will also be interested in: CONTAINERIZED BULK HANDLING